Medical MIM Parts

MIM Medical Parts Gallery

Our MIM parts are used as orthodontic brackets, surgical instruments, forceps, scissors, sewing units, drug delivery devices, surgical implants, hearing aids, dental equipment & implants, B-ultrasonic instrument parts. We provide various materials with excellent properties to meet all your special device demand. Additional post-process can offer you any surface appearance finishes.

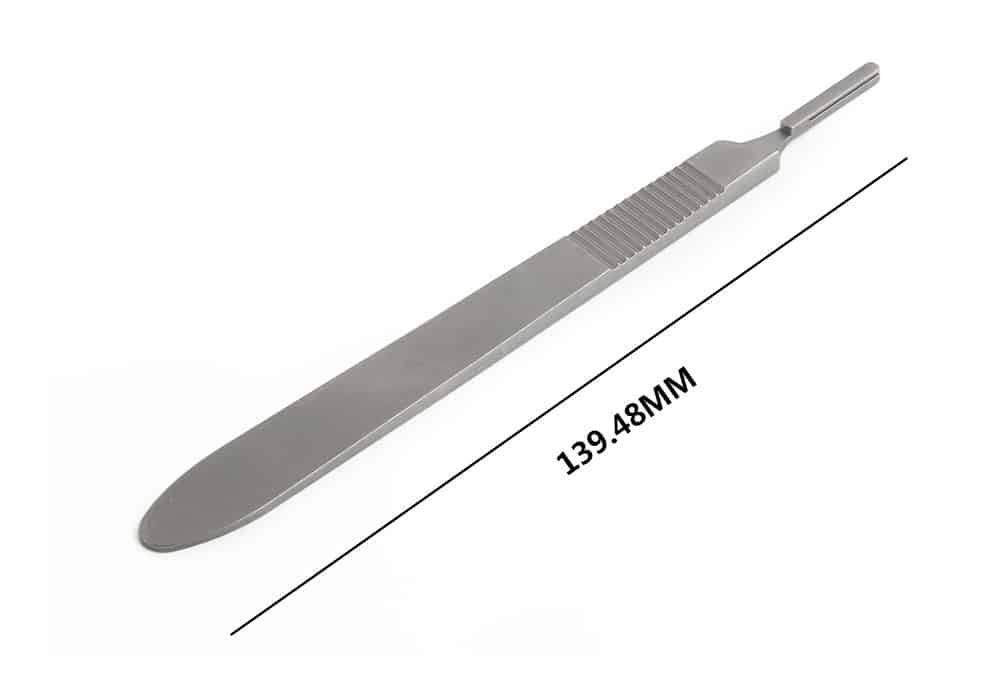

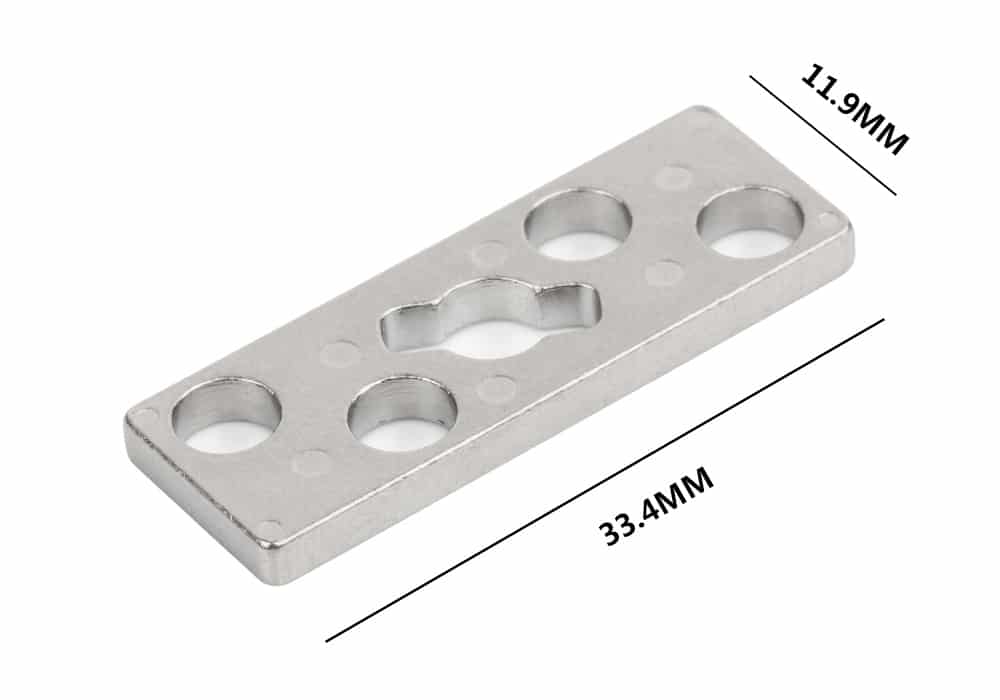

Surgical Instrument

- Material: Stainless steel 17-4PH

- Size: 3.29mm×5.10mm

- Density: ≥7.6g/cm³

- Manufacturing process: Metal injection molding, Magnetic grinding.

- Material: Stainless steel 17-4PH

- Size: 139.48mm

- Density: ≥7.6g/cm³

- Manufacturing process: Metal injection molding, Magnetic grinding.

- Material: Stainless steel 17-4PH

- Size: 11.9mm×33.4mm

- Density: ≥7.6g/cm³

- Manufacturing process: Metal injection molding, Magnetic grinding.

- Material: Stainless steel 17-4PH

- Size: 19.83mm

- Density: ≥7.6g/cm³

- Manufacturing process: Metal injection molding, Magnetic grinding.

- Material: Stainless steel 17-4PH

- Size: 19.1mm×11.45mm

- Density: ≥7.6g/cm³

- Manufacturing process: Metal injection molding, Magnetic grinding.

- Material: Stainless steel 316L

- Size: 17.42mm

- Density: ≥7.8g/cm³

- Properties: Tensile strength of 510 MPa, Yield strength≥180 MPa, Hardness of 120HV10.

- Manufacturing process: Metal injection molding, Magnetic grinding.

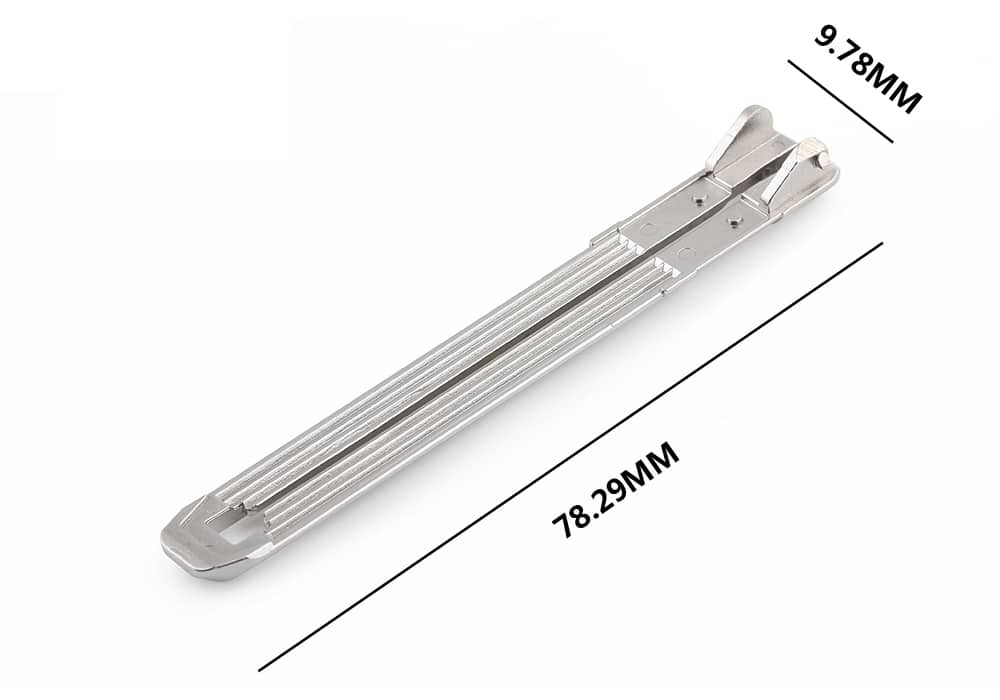

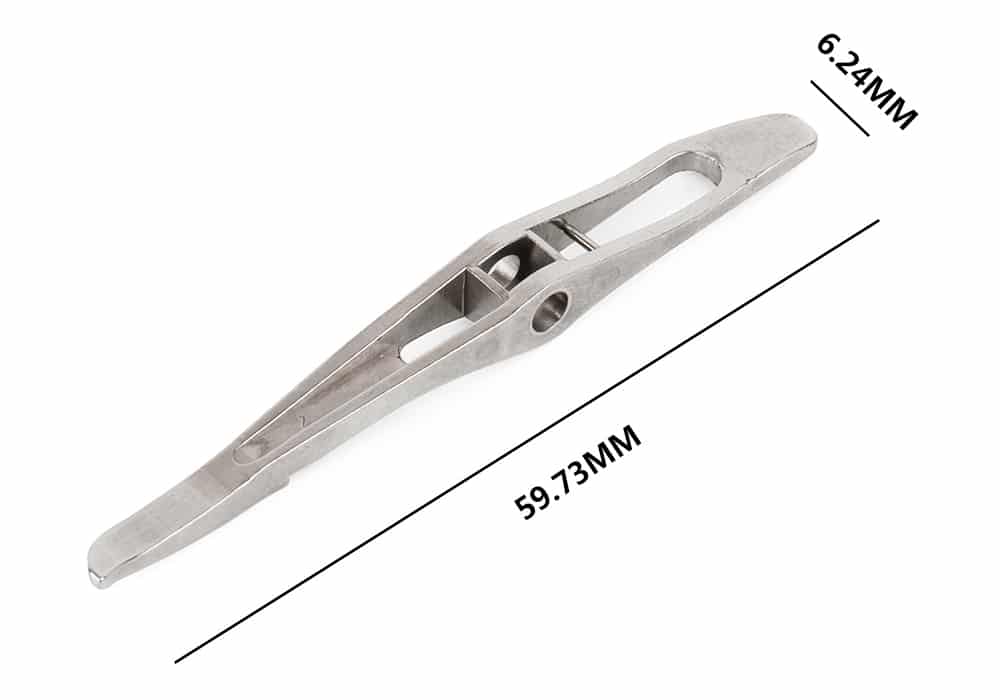

Sewing Unit

- Material: Stainless steel 17-4PH

- Size: 9.78mm×78.29mm

- Density: ≥7.6g/cm³

- Manufacturing process: Metal injection molding, Magnetic grinding.

- Material: Stainless steel 17-4PH

- Size: 6.24mm×59.73mm

- Density: ≥7.6g/cm³

- Manufacturing process: Metal injection molding, Magnetic grinding.

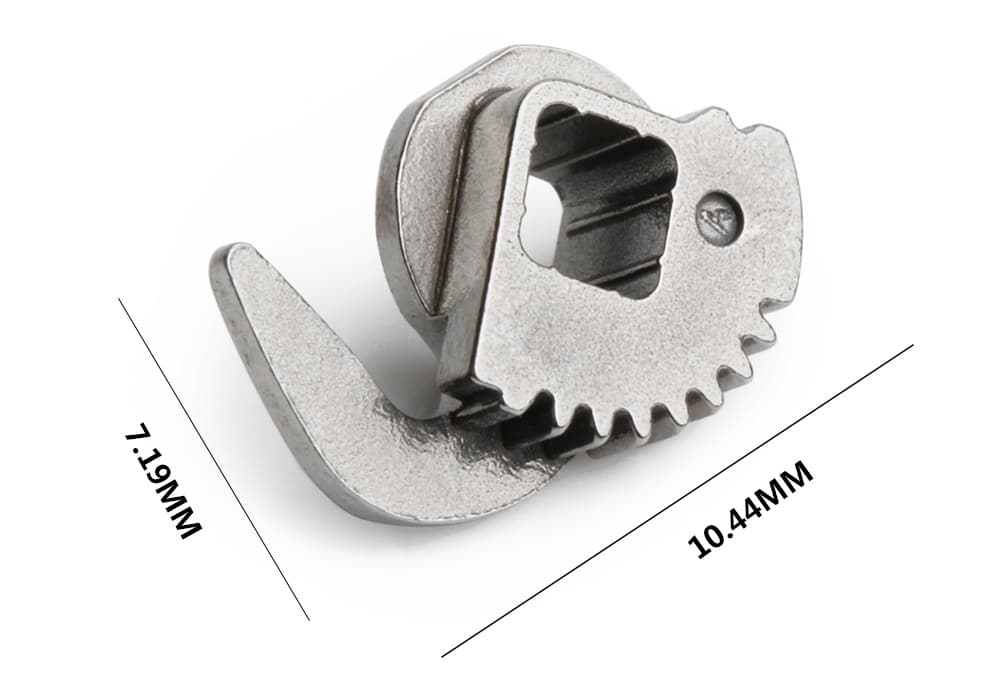

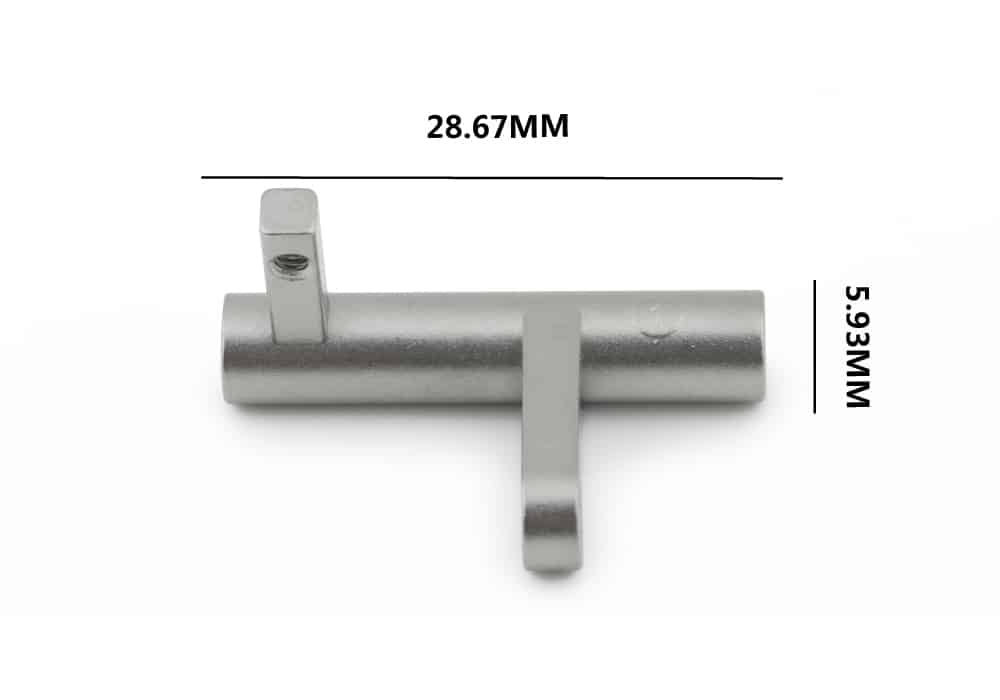

B-ultrasonic Instrument

- Material: Stainless steel 17-4PH

- Size: 10.44mm×7.19mm

- Density: ≥7.6g/cm³

- Manufacturing process: Metal injection molding, Magnetic grinding.

- Material: Stainless steel 17-4PH

- Size: 5.68mm×5.52mm

- Density: ≥7.6g/cm³

- Manufacturing process: Metal injection molding, Magnetic grinding.

- Material: Stainless steel 17-4PH

- Size: 28.67mm×5.93mm

- Density: ≥7.6g/cm³

- Manufacturing process: Metal injection molding, Magnetic grinding.

- Material: Stainless steel 316L

- Size: 20.38mm×11.20mm

- Density: ≥7.8g/cm³

- Properties: Tensile strength of 510 MPa, Yield strength≥180 MPa, Hardness of 120HV10.

- Manufacturing process: Metal injection molding, Magnetic grinding.