Custom MIM Materials

Introduction

As development of metal manufacturing technology, our customers are looking for high performance MIM parts in their final unique products. Their special requirement range from better strength and density to more duration. In order to keep our metal injection molding (MIM) business up with new requirement, reduce limitation in design for manufacturing. Feedstock, as the foundation of MIM process, is optimized by our professional engineering team. ZCMIM selects the right blend of MIM materials to create a personalized component with the highest standards. Our company provide the best MIM parts with the most suitable material.

MIM Material Option

Once consider of metal injection molding and powder metallurgy technology, we are always impressed by some key characteristics. ZCMIM can provide custom feedstock to enhance material performance. In order to fully control MIM material ingredient, recipe and variable. We can guarantee precise composition and consistency of every component.

Material Composition Affection

In MIM process, custom feedstock and precise powder composition will enhance grain structure and boundary condition. This provides MIM parts with optimal density, ultimate strength, the best elongation and reliable capability. ZCMIM custom feedstock can specify metal powder size distribution and binder composition for all your projects. We can satisfy all your mechanical performance and properties requirement.

Various Material Selection

ZCMIM specialize in various ferrous and non ferrous alloy, such as stainless alloy, low alloy steel, copper alloy and nickel alloy. These MIM materials contribute most of our MIM business. We also have experience for special alloy as F15(Kovar) and F75(Cobalt-Chromium).

Our custom MIM material has wide variety, we divide these materials into following categories:

Ferrous alloy: Stainless alloy, low alloy steel and F15 (Kovar). All these metal have excellent strength in reason of iron-based composition, and widely applied in medical and automotive industry.

Tungsten alloy: Our tungsten alloy has high tensile strength and corrosion resistance. Typically tungsten-copper alloy parts are best choice for heat-resistance, ablation-resistance requirement with high thermal and electrical conduction.

Special alloy: Our special alloy in MIM process including: titanium alloy, cobalt-chromium, nickel base super alloy, molybdenum alloy.

MIM Feedstock

Feedstock is a combination of specific metal powders and plastic or wax binder, which is applied to MIM process as MIM parts basis. Very fine spherical metal powder is mixed with binder system, which normal are plastic or paraffin wax. The intent of binder system is to determine final parts shape geometry in MIM molding process, while internal metal powder follow the same structure. Final feedstock is approximate 40% binder and 60% metal in volume, metal powder size ranges from 10 to 25 microns. All these materials are mixed together and extruded into pellets. The pellets will be fed into injection molding machines, and formed into MIM parts first stage – ‘green part’. Although following operations will create final net-shaped metal parts, feed stock is the basic structure.

In ZCMIM, our professional engineering team will analyze feedstocks composition, and recommend the best solutions for every project. We provide a wide range of metal options for our customers. Customers can select more metal mixture option they prefer with our assistance. Our common feedstocks including: stainless steel 316L, stainless steel 304, stainless steel 402, stainless steel 17-4PH, Titanium or copper. We also create custom blend powders to satisfy specific products requirements. Such as mechanical properties, weight limitation and high temperature environment.

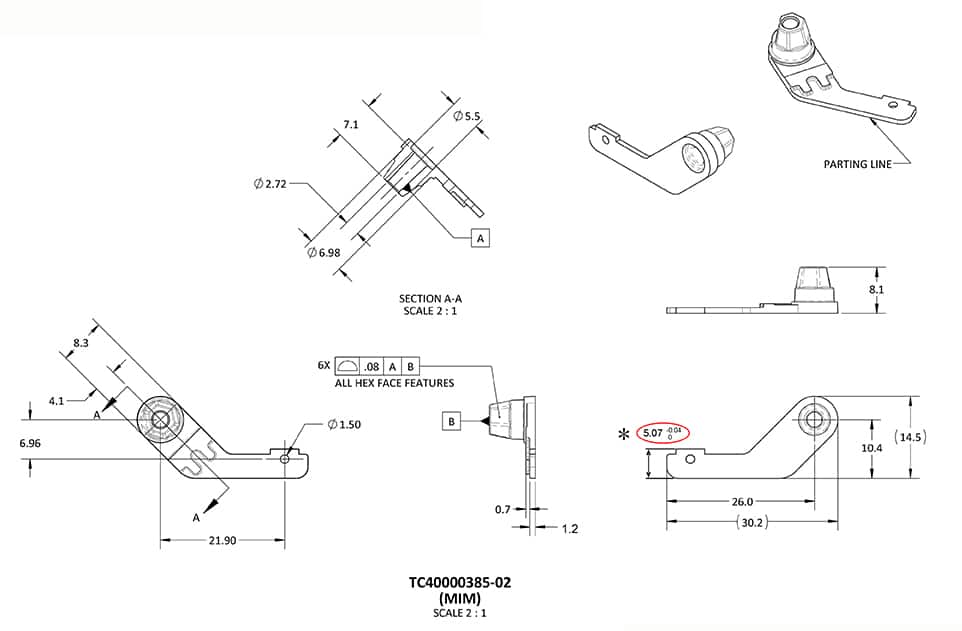

Dimension Control in Process

Custom alloys formulation add a complexity layer in feedstock producing process. It’s significant to obtain a sound, uniform and repeatable feedstock mixture. In order to optimize consistency of mechanical performance and properties. When incorporate multiple materials into feedstock, we need precise metallurgic knowledge with very tight control in place. Our consistent dimensional control in MIM process are not only for divided parts, but also for batches. ZCMIM can predicate repeatable parts shrinkage during sintering process each time.

With our emphasis on consistent dimensional control, you can spend more time and investment for your design optimization on performance without traditional restraints.

Freedom to Design Best

In all metal-working projects, the most important issue is final products performance, especially for functional parts. ZCMIM can apply customization MIM feedstock to satisfy your design requirement in both technology and performance. However, this is impossible by other metalworking methods. Our engineering team will recommend the best MIM material options to fit your part. We will create the perfect fusion for optimal performance. Never pick a simple material without any practical production data.

In MIM process, inappropriate material usage will impact all final parts performance. This is the reason that particular material characteristics’ selection combine with tight fine-tuning will provide better parts performance. Furthermore, comparing to other metal injection methods, binder materials combine with proprietary alloys will create tighter tolerance, high density and smooth finished parts. Since ZCMIM control feedstock development in variation and MIM production in process. We can provide higher accuracy control in batch-to-batch with huge capability. This is our unique advantages in MIM manufacturing industry.

Design for Performance

MIM technology plant component geometry with function and strength need in corresponding area. Meanwhile, it can consolidate multiple components into one single MIM parts with strong geometry. This make our MIM parts are closer to original design intent, rather than multiple parts assembly. Consolidation MIM parts will also reduce risk of potential part failure. Since MIM design involves all required features, complexity of structure will never increase additional cost. Otherwise, conventional method need to consider deburring or chamfering on casting parts, which mostly increase to higher parts price with additional complex geometries.

There is no doubt that MIM is the most suitable way of complex and precise parts production with high performance and quantity. All this process start with ZCMIM custom formulation feedstock. We will deliver high-performing parts for any projects, no matter how complex your design parts.

As you are interested in our custom material for your next project, contact us for more information.