MIM 4605

Introduction

MIM 4605 is a low alloy steel with element of carbon, nickel and molybdenum. This steel can achieve high hardness and strength by quenching and tempering heat-treatment. In common quenching and tempering process, MIM 4605 provides various strength and wear resistance, with the high hardness of 36HRC.

The typical hardness can reach to 48 HRC with specific heat-treatment. In addition, post-processing of plating and coating are also applied to increase corrosion resistance. The common application of 4605 steel including: automotive, consumer products, powder hand tools.

MIM Steel 4605

Common Chemical Composition

| MIM 4605 | Iron | Nickel | Molybdenum | Silicon | Carbon | Sulphur | Phosphorus |

| Percent by Weight | Bal. | 1.50-2.50 | 0.20-0.60 | 1.00 | 0.40-0.60 | 0.03 | 0.035 |

Mechanical Properties (Sintered)

| Material | Density | Tensile Strength | Yield Strength(0.2%) | Hardness | Elongation(% in 25.4mm) |

| MIM 4605 | ≥7.50g/cm³ | ≥600Mpa | ≥230Mpa | 100HRB | ≥10% |

Mechanical Properties (Low Hardness)

| Material | Density | Tensile Strength | Yield Strength(0.2%) | Hardness | Elongation(% in 25.4mm) |

| MIM 4605 | ≥7.60g/cm³ | ≥1150Mpa | ≥1030Mpa | 36HRC | ≥5% |

Mechanical Properties (High Hardness)

| Material | Density | Tensile Strength | Yield Strength(0.2%) | Hardness | Elongation(% in 25.4mm) |

| MIM 4605 | ≥7.50g/cm³ | ≥1550Mpa | ≥1400Mpa | 48HRC | ≥3% |

MIM 4605 Process

MIM 4605 is applied in structural applications with high strength and hardness requirements. It is one of the most popular MIM grades, primary in manufacture of general engineering and automotive. Steel 4605 is a hardenable nickel steel, it can be heat treated to achieve higher strength and hardness.

Both nickel and molybdenum can retard the transformation from austenite to ferrite&cementite in high temperature. This will increase the harden-ability of low alloy steel and the ease of martensite forming. Finally, provide the fine martensite micro-structure in tempering process, and achieve preferred combination of strength and toughness.

In MIM processs, the sintering process has significant effect on mechanical properties and micro-structure of MIM 4605.

Sintering Parameter

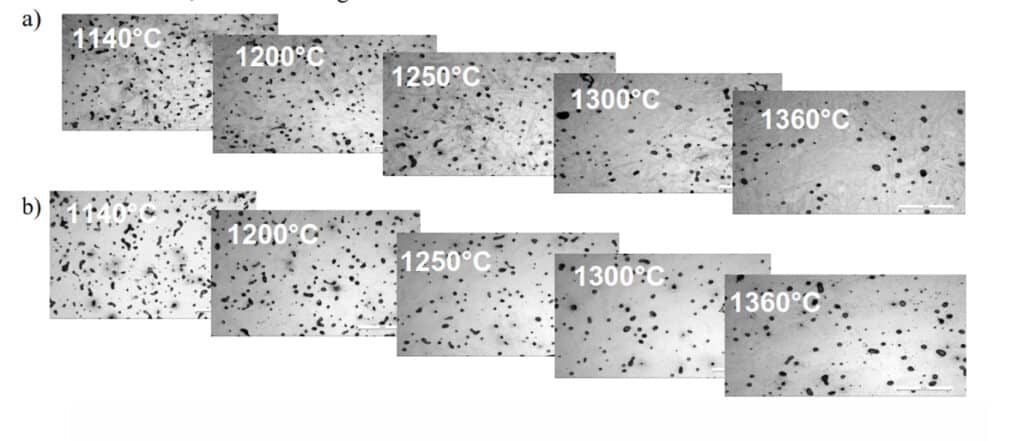

Sintering temperature is between 1140°C and 1360°C, the holding time in at least 2 hours. The sintering atmosphere is nitrogen, after sintering, all sintered parts should be cooled slowly in the nitrogen atmosphere.

Additional Heat Treatment

Solution annealing for 60 minutes at 830°C, then oil quenching and tempering at 200°C for 1hour, air cooling finally.

Carbon Content

The final carbon content in MIM-4605 parts are within the target specification of 0.4-0.7%. In sintering temperature between 1140°C and 1360°C, all C content is well controlled in all powder variants.

MIM 4605 Sintering

Densification

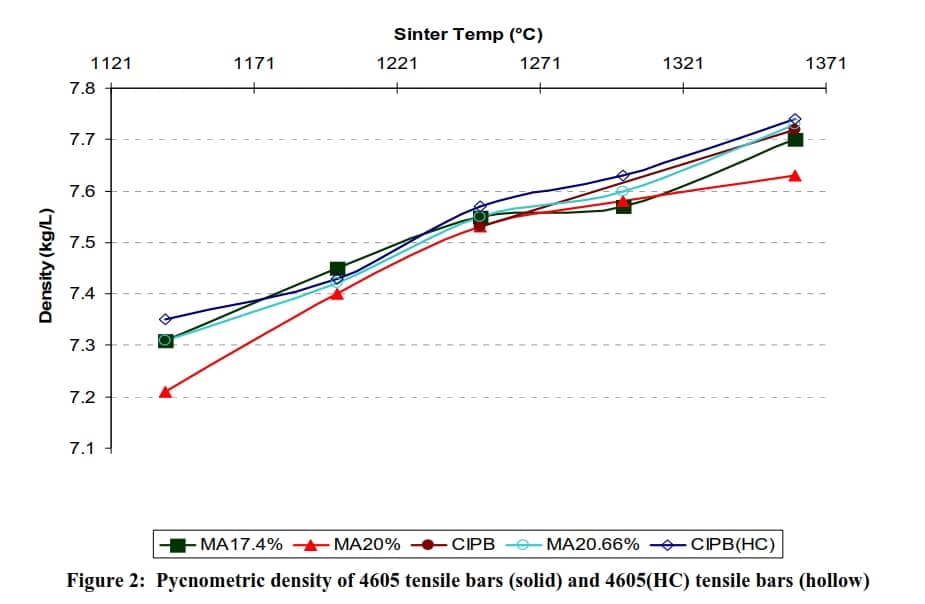

As the sintering temperature increase, the densities of sintered parts increase accordingly. Normally, all MIM 4605 powder will achieve the highest or equal values in the sintering temperature range between 1140°C and 1360°C.

From the above image, the number of pores reduce significantly with increasing sinter temperature. Meanwhile, there is also a coarsening of pores.

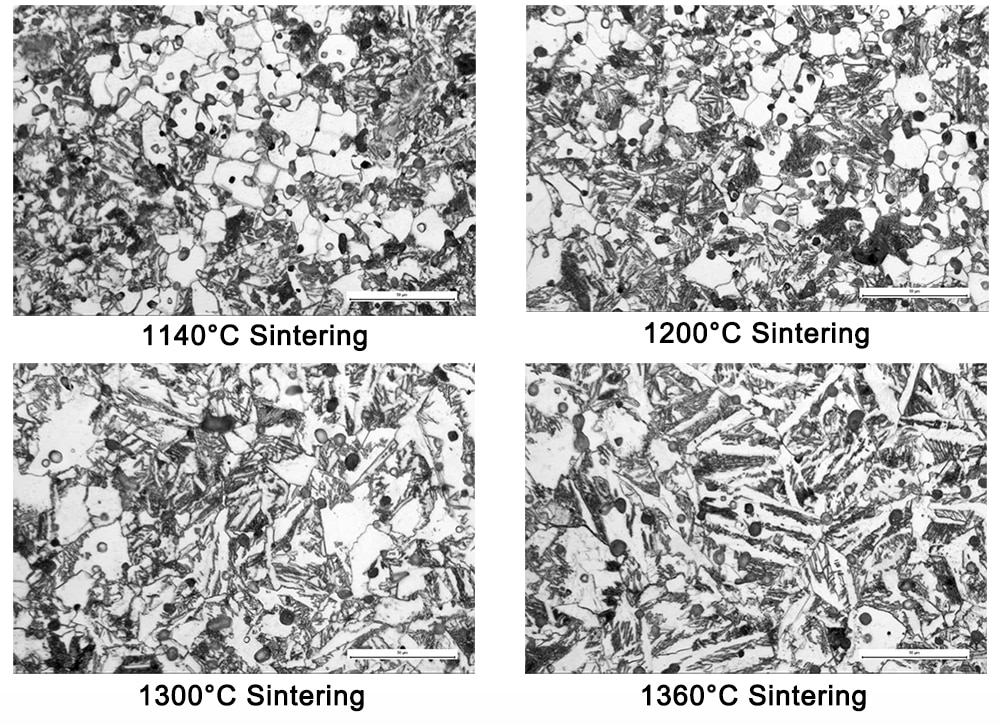

Micro-structure

From the etching micro-structure, in low sintering temperature 1140°C, there are light Ni-rich phase with bainite surrounding. As the temperature increases, the bainite transformation start occur, then followed by coarsening. Finally, achieve homogeneous structure of coarse-lath bainite.

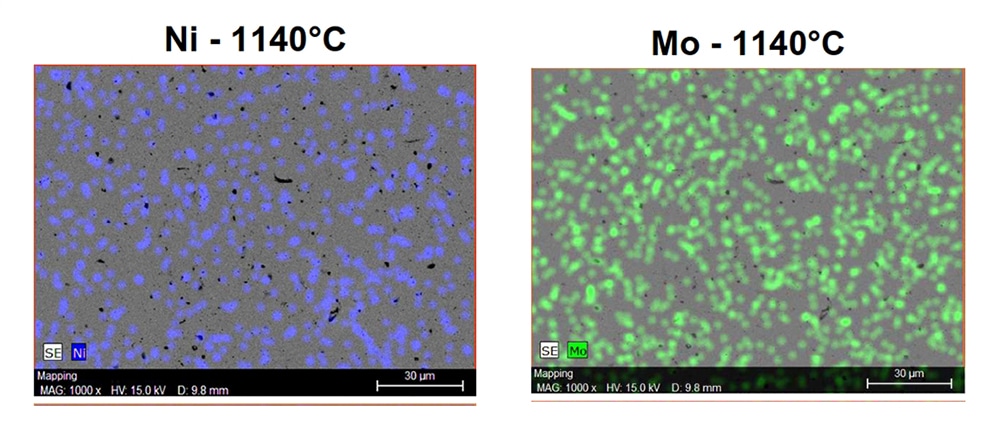

In EDS images, the Ni and Mo distribution is homogeneous at 1140°C. As temperature increases, there is no discernible difference.

Mechanical Properties

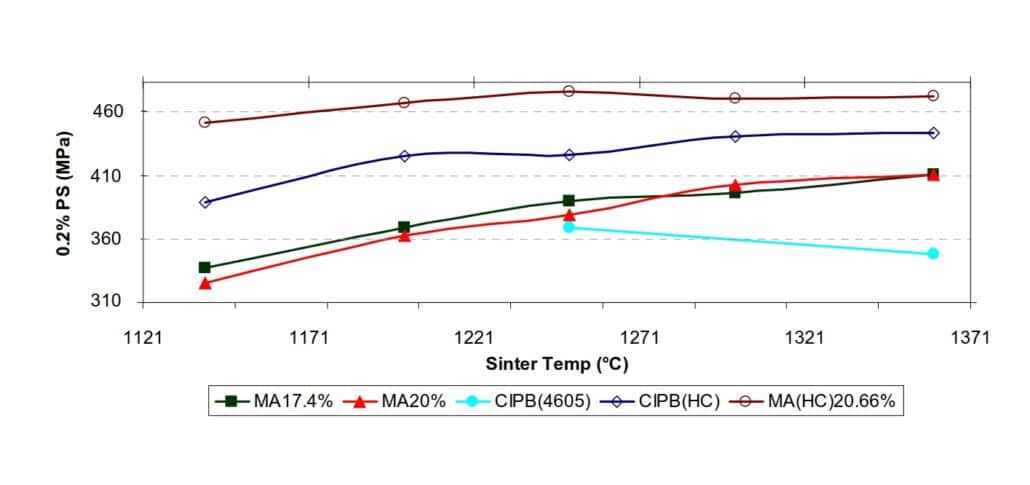

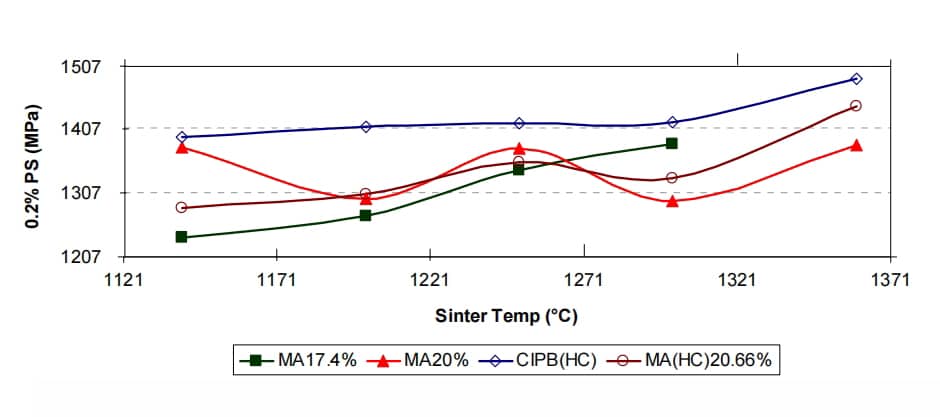

Proof stress values in normal MIM 4605 powder exceed the minimum MPIF standard. Higher carbon content feedstocks result in higher values of 30-60 MPa.

After heating treatments, the values of proof stress increase significantly. The highest value will reach to nearly 1500 MPa.

MIM 4605 vs MIM 4140

MIM 4605 and 4140 are common low alloys steels for structural applications with high strength and hardness.

Comparison of 4605 and 4140 Composition

| Chemical Composition | Fe | Ni | Cr | Mo | C | Si |

| MIM 4605 | Bal. | 1.5-2.5 | – | 0.2-0.5 | 0.4-0.6 | 1.0 |

| MIM 4140 | Bal. | – | 0.8-1.2 | 0.2-0.3 | 0.3-0.5 | 0.6 |

MPIF Standard 35 Properties

| Alloy | Density | Hardness(HRC) | YS(MPa) | UTS(MPa) | Elongation(%) |

| MIM 4605(Q&T) | 7.5 | 46 | 1300 | 1480 | 3 |

| MIM 4140(Q&T) | 7.5 | 48 | 1050 | 1380 | <1 |

Conclusion

ZCMIM has nearly 10 experience in MIM 4605. We apply different alloy power size, sintering temperatures, heat treatment to achieve specific mechanical properties. Contact us for your next 4605 MIM project.