What is Metal Injection Molding

Introduction

Metal Injection Molding (MIM) is an advanced metalworking technology. This innovative technology is suitable for mass production of complex-shaped metal parts. It mixes finely-powdered metal with binder materials to create MIM feedstock, then mold and form this feedstock into required shapes, finally debind and sinter into pure metal products. In reason of its high capability of complex metal parts with simplifying production, MIM parts are applied widely in aerospace, medical, electronics, automotive, agriculture, and other markets.

As we know, Powder injection molding encompasses Metal Injection Molding and Ceramic Injection Molding. These technologies are major manufacturing methods for new products’ development.

Overview of Metal Injection Molding

There are several technological issues before metal injection molding process could be applied industrially. Such as:

The homogeneous powder-binder mix should have sufficient viscosity for injection molding.

Economical binder removal methods provide debinded part geometry retention.

Sintering to high density metal parts with high dimensional accuracy.

The main process of metal injection molding including:

Feedstock Preparation

Feedstock is the raw materials of metal injection molding, its primary composition are metal powders and thermoplastic binders. The properties of metal powders will determine the final properties of metal injection molded products. Meanwhile, the binder is an intermediate aid in injection molding, then remove it from the final products after MIM injection molding.

The MIM feedstock usually granulated in size of several millimeters. We can purchase feedstock from international suppliers like BASF, or our engineering team can manufacture custom feedstock with unique properties and requirements.

MIM Injection Molding

This MIM injection molding process is similar to plastic injection molding, we can apply MIM injection molding to produce the variety of part geometries. In this process, the green MIM parts are formed as the forming of plastic parts.

Debinding

In the debinding process, various methods will remove binder materials from the injection molded MIM parts – green parts. Then left an interconnected pore network without any geometrical destroy – yellow parts. After this debinding process, there is still some binder in parts to holding metal powders together. But this residual binder will evaporate quickly from this pore metal network in the initial phase of sintering. Meanwhile, sintering necks grow between the metallic particles to keep parts geometries consistently.

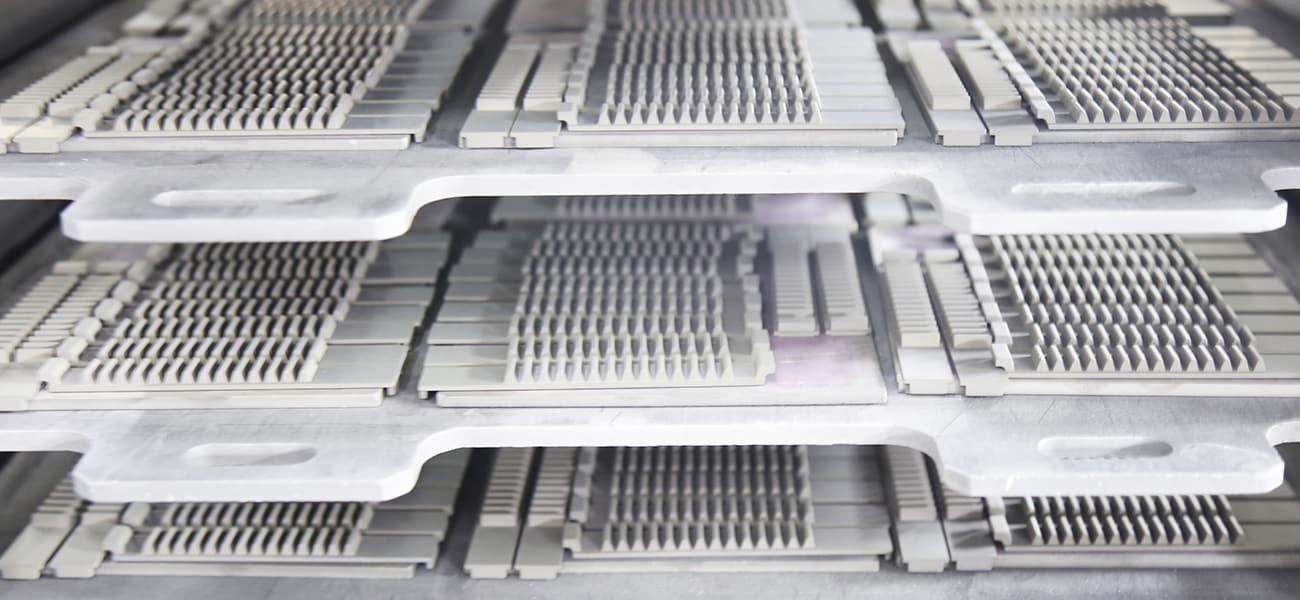

Sintering

The sintering will eliminate the most pore volume by binder materials occupation. Therefore, the yellow MIM parts will shrink with linear rate of 15 to 20 % after sintering process. Once required, sintered MIM parts are able to process by conventional metalworking methods, in the same way as cast, wrought or forged metal parts. Such as heat treatments, surface treatment.

Powders for Metal Injection Molding

Metal Injection Molding provides the diversity of MIM materials, from stainless steel to titanium and supper-alloys. In this process, metal particle size distribution will determine the sinterability and surface quality of final MIM parts. As the general rule, the finer metal powder, the better performance.

Carbonyl Iron and Nickel Powders

There are very fine carboyl iron and nickel powders in industrial production. These metal powders have spherical structure with good flowability. Their particle sizes are less than 10 µm, this is finer than common atomized and reduced iron powder in Powder Metallurgy of uni-axial powder compaction.

Carbonyl iron powders provide excellent sintering properties. The small particle size result in high density, exceptional strength and surface texture. In addition, the uniform spherical shape give rise to high dimensional accuracy. Furthermore, ferrous MIM alloys are normally based on carbonyl iron and nickel. MIM manufacturers can mix these powders with elemental or mater alloy powders, in order to achieve required alloy compositions.

Water and Gas Atomized Powders

Normally, prealloyed metal powders are applied for high alloy steels, nickel and cobalt base alloys. These kinds of alloy powders are gas atomized with a spherical particle shape. In some specific case, we also need to add irregular particle shapes of water atomized powders. As atomizing technique improvements, metal powder manufacturers can offer different kind of high alloy steel powder with average particle size under 10 µm.

Binders and Debinding Techniques

Binders are essential in the forming process of MIM parts, its removal process (debinding) is also a challenge in metal injection molding.

Binders

As developments in binders compositions, the binder is the most critical part in MIM forming, it should fulfill several tasks as following:

- It can incorporate with high volume of fine metal or ceramic powders, normally 60 % in volume.

- Binder can be plastified and injection molded at high temperature.

- Removal process of main binder constituent is a short and environmental friendly process.

- After debinding, the backbone binder still provides enough strength to hold the main structure of debinded parts.

- It has a regular granular form for easy feeding into injection molding machines.

- Binder has consistent and uniform properties from different batches.

- Recycling of runners and green scrap

Therefore, we can say that the development of Metal Injection Molding technology is the development of binder compositions and the corresponding debinding technology.

Thermal Debinding

In the original MIM process, the binders are mixtures of a ploymer (polyethylene, or polypropylene), a synthetic or natural wax, and stearic acid. These kinds of binder systems are successfully applied in common MIM projects.

On the base of this binder type, the feedstock is easy to mold. But the debinding process requires very careful heating process with 24 or more hours, before the interconnected porosity network was created. The remaining binder is easily evaporated in sintering process through porosity network, result in no destroy on part geometries.

Catalytic Debinding

The invention of Catamold system by BASF provide significant progress in reliable MIM manufacturing for volume production. This binder is based on polyoxymethylene (POM), so it is called as polyacetal binder system. It has excellent mold-ability and outstanding geometries’ retention.

Catalytic debinding process is in a gaseous acid environment at a temperature of approximate 120 ℃ (below binder softening temperature), such as high concentrated nitric or oxalic acid. These acids act as a catalyst in the decomposition process of polymer binder. In addition, the reaction products must be burnt in gas flame above 600℃. This catalytic debinding will create interconnected porosity in nearly 3 hours.

The catalytic debinding method has a significant proportion of MIM parts production, especially in electronic industry.

Solvent Debinding

Solvent debinding is the most successful technique in new debinding development. This binder composition contains a dissolved constituent in low temperatures. Therefore, porosity network will create once molded parts immerse in the solvent.

Although water-soluble binder compositions are preferred, in reason of its easier handling than organic solvents. Acetone or heptane are the most common solvents in debinding. After solvent debinding, the contaminated solvent will be distilled and recycled.

Solvent debinding will take longer time than catalytic binder removal, but its investment and operation cost are lower. Therefore, solvent debinding is still competitive, it also has environmental advantages than other debinding process.

Metal Injection Molding Feedstock

In normal MIM manufacturing process, we need to make the fundamental decision of metal injection molding feedstock. Whether to purchase feedstock from professional suppliers, or develop custom feedstock compositions for specific requirements. However, no matter which method to get feedstock, the most important factor to successful MIM production is the absolute batch-to-batch consistency. Otherwise, the defects will occur in molding process, and distortion in sintering process.

MIM Injection Molding

In MIM injection molding, the metal injection molding industry can rely on the technical background and experience in plastic injection moulding. Injection molding machine manufacturers provide comprehensive technical support of Powder Injection Molding, there are some dedicated PIM facilities to improve efficiency. In addition, there are some minor modifications to optimize MIM injection molding, such as the injection cylinders are adapted for abrasive properties of MIM materials.

Except injection molding machines, MIM injection molding also requires experienced mold makers, mold design software, part handing devices and so on.

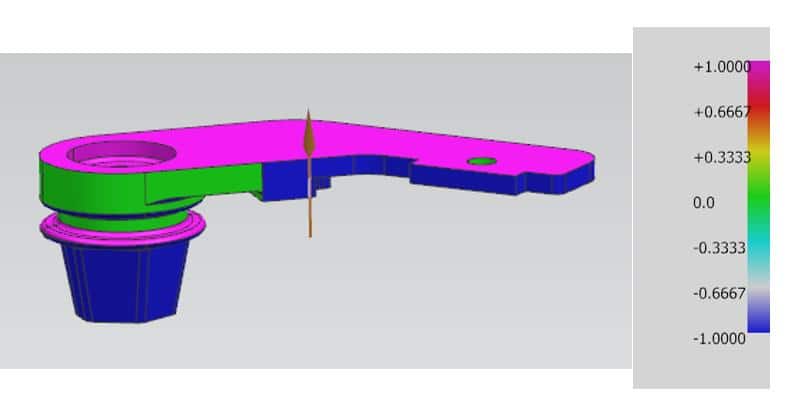

Simulation Tools and Part Design

Computer simulation of injection molding is an advanced technology, we can analyze every detail of mold filling in 3D. The following graph is computer simulation of Deka Industrial MIM Case.

MIM Sintering

MIM sintering is similar to that in traditional Powder Metallurgy, it can be finished in continuous or batch type furnaces. We can consider sintering as separate units or integrate into a production line. Different from sintering in Powder Metallurgy compacts, Metal injection Molded parts will shrink significantly during sintering. Therefore, MIM sintering requires higher temperature and longer cycle time than PM. The sintering process types and conditions are determined by materials composition and quantities.

Sintering process is normally in protective atmospheres or in vacuum, at the specified temperatures below the melting point of metal alloys. Before sintering, green MIM parts should go through debinding (either catalytic, thermal or solvent debinding) process, In order to get brown MIM parts with open pore network, the backbone binder can hold metal powders and guarantee geometry retention of brown MIM parts.

Conclusion

Metal Injection Molding Advantages

The metal injection molding technology has unique capability of small size, high geometry complexity, high strength, high surface finish and high dimensional tolerance. It is a competitive net-shape process, because it avoids high cost machining operations. In addition, new design in metal injection molding can combine multi-parts assembly into one single component.

Metal Injection Molding Limitations

Metal injection molding process has high degree of automation, it is competitive in high-volume production, especially for 20,000 to millions per year. Comparing to casting metals and alloys, MIM is limited by high raw material cost. This is the reason why MIM parts are in small size, as the material cost take a smaller portion in total manufacturing cost. MIM process is environmental friendly with less energy consumption, and there is little waste in reason of MIM net-shape capability.

The diversification, specialization and availability of metal injection molding result in rapid increase in MIM parts. These MIM parts are applied widely in various industries, such as medical, automotive, electronics, aerospace, and industrial.

Contact our engineering team for more information about Metal Injection Molding (MIM).