MIM 420 Stainless Steel

MIM 420 Introduction

Stainless steel 420 is a martensitic heat-treatable stainless steel, it has high strength and hardness, as well as corrosion resistance. It is a common steel in extensive applications, such as surgical and dental instruments (medical), ball bearings, gear shafts, pump and valve components (industral), fasteners, gauges, hand tools (electronic), high-end cutlery (consumer).

Stainless steel 420 is also applied popularly in both Metal Injection Molding (MIM) and Additive Manufacturing (AM) technologies. Qualification of SS 420 and other high-strength alloys accelerate deployment of successful mass-production. Our high qualified MIM 420 feedstock can achieve the MIPIF 35 standards for Metal Powder Industries Federation (MPIF).

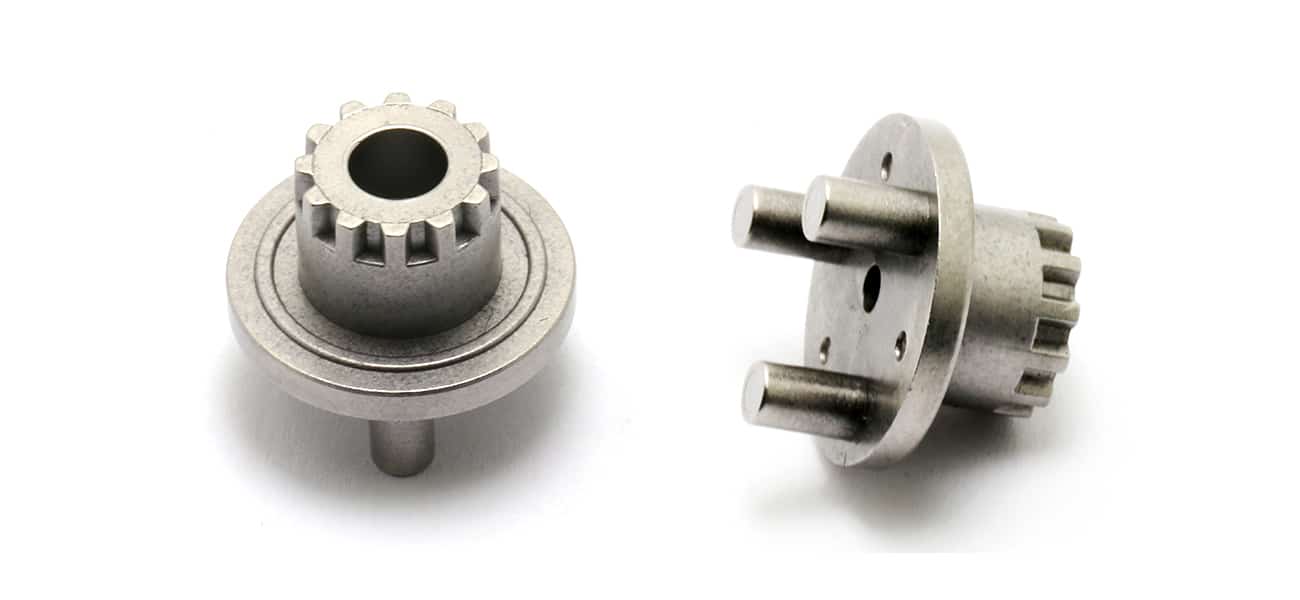

MIM 420

Chemical Composition

The common composition of MIM 420 after sintering is as following:

| Stainless steel 420 | Iron | Silicon | Carbon | Chromium | Phosphorus | Manganese | Sulfur |

| Percent by Weight | BaL. | 1.00 | 0.15 | 12.00-14.00 | 0.040 | 1.00 | 0.030 |

Mechanical Properties

| Material | Density | TensileStrength | Yield Strength(0.2%) | ImpactStrength | Hardness | Elongation(% in 25.4mm) |

| Stainless Steel 420 | ≥7.55g/cm³ | ≥750Mpa | ≥600Mpa | 82J | 30-39HRC | ≥1% |

Martensitic Stainless Steel

Martensitic steel is a stainless steel grade, it can be hardened and strength through heating and aging treatments.

Martensitic stainless steel is popular for its strength, corrosion resistance and durability. These excellent quality make it an excellent choice for various applications. Such as medical instruments, mechanical valves, turbine parts, mechanical instruments.

Chemical Composition

Similar to all stainless steels, the critical element of martensitic steel is chromium, with composition of 11.5-18%. Other common elements include up to 0.75 % carbon and nickel. High carbon content provides a strong molecular structure martensitic structure for martensitic stainless steel, while low nickel content limit its corrosion resistance.

The common types of martensitic stainless steel are stainless steel 410, stainless steel 420, stainless steel 440. These martensitic stainless steel has similar reaction as high carbon steels in heat treatment processing, the maximum quenched hardness depends on the final carbon contents.

Normally, the martensitic are harden by heating to high temperature with rapid cooling. As the hardenability of martensitic steel is very high, this is referred to as “air hardening”. The structure of as-hardened martensitic is quite brittle, therefore additional processing is required to satisfy different application requirements.

- Reheat materials at low temperatures to relieve the micro-structure stress.

- Reheat in slightly higher temperature to soften (tempering) to intermediate hardness levels.

- Process annealing by heating just below the critical temperature.

- Full annealing by heating just above the critical temperature with slower cooling.

Stainless steel 410

Stainless steel 410 is a general purpose martensitic steel, its hardness level is changed with slight variations in hardening and tempering

Stainless steel 420

Stainless steel 420 covers the carbon range from 0.15% to 0.45%, therefore it has relatively wide range of hardness in both hardening and tempering conditions. This steel can be hardened to HRC 40-50. Versatile hardness of SS 420 make it desirable for tempered products for specific applications

Stainless steel 440

Stainless steel 440 has higher hardening capability than 410 and 420, but limited formability in the annealing conditions. This grade steel can be hardened over HRC 50, this makes it attractive for blade applications. The higher hardness makes blades remain sharper for a longer time.

Characteristics of Martensitic Steel

Martensitic steels have multiple propertie for a wide range of applications, these steels can combat comparatively mild corrosive conditions with maximum strength and stiffness. The annealed martensitic steels have the best forming characteristics, while the hardening treatment follows forming operations generally.

Weldability

Martensitic stainless steel is typical brittle, most steels react unfavorably to welding process. Furthermore, additional quenching and tempering can decrease brittleness and increase applications. High carbon martensitic steel is not suitable for welded applications, while stainless steel 410 is welded with relative ease.

Magnetism

Most martensitic stainless steels are magnetic, the magnetic property is stable in both annealed and hardened conditions.

Formability

Stainless steel 420 covers the carbon range from 0.15% to 0.45%, therefore it has relatively wide range of hardness in both hardening and tempering conditions. This steel can be hardened to HRC 40-50. Versatile hardness of SS 420 make it desirable for tempered products for specific applications

High Strength

Martensitic stainless steels are applied primarily for components with high mechanical properties. Comparing to other stainless steel, the degree of corrosion resistance also limit the range of applications. There are some superficial rust stain on the surfaces frequently. Limited corrosion resistance can be achieved in the annealing condition, while the highest corrosion resistance is attained in the hardening or tempering conditions.

Hardening Method of Martensitic Stainless Steel

One specific advantage of martensitic stainless steels is that, these steels become stronger and harder after heat treatments. The common hardening methods to increase the strength of martensitic stainless steels.

Age Hardening

This method hardens steels by heating to form precipitates, in order to prevent defect movements in molecular structure. All these defects in containment make steels stronger and harder. After heating, store parts at an elevated temperature until the process is complete.

Annealing

Annealing can provide homogeneous molecular structure by heating process, and remove stress of steels. This makes the steels softer and easier to manipulate.

Quenching and Tempering

Quenching and tempering process includes some complex steps: harden steels by heating, then cooling rapidly, then heating again. After the initial heating and cooling steps, the steels are hard but very brittle. The second heating will bring the steels back to ductile.

MIM 420 Applications

Medical/ Surgical

MIM 420 is a desired material for components like locking articulation bars, as its high hardness and excellent corrosion resistance. Advanced MIM technology provides cost-effective tooling design and fabrication in mass production.

Robotic surgical systems require high precise motion system with small intricate components, these components normally have high tolerance and complex structure. In order to provide better motion, enhanced visibility and high precision level.

Aerospace

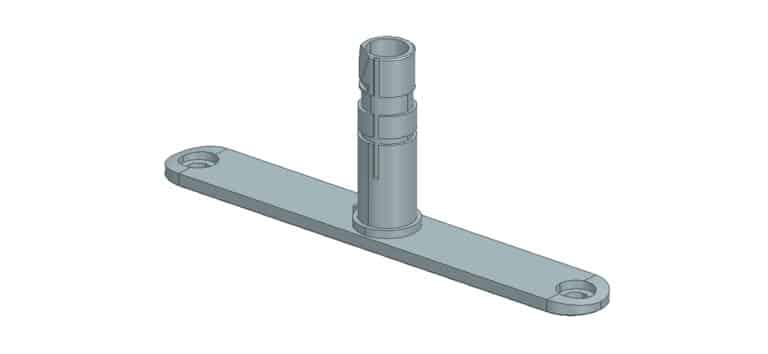

Valve nozzle adapters connect different nozzle with filed system, multiple version of adapters accommodate various nozzle geometries and sizes. Stainless steel 420 is perfect for these adapters, in reason of its excellent corrosion resistance and hardness.

In MIM industry, we can produce millions of components with serious size molds. This reduces leading time and cost over conventional manufacturing process.

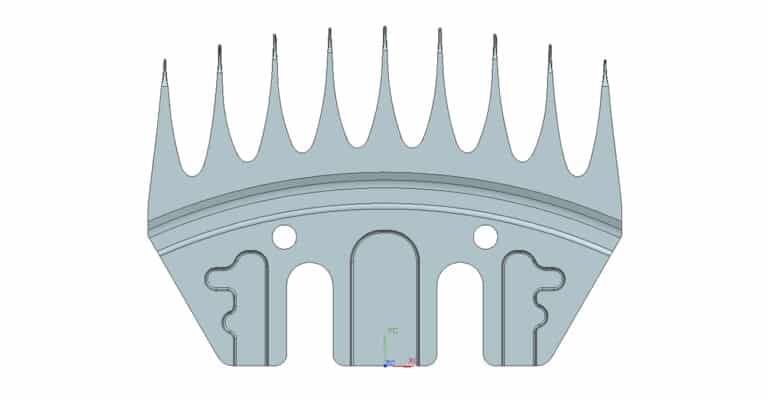

High-volume Manufacturing

Screw extruder elements have complex features with spline, these structures must be optimized for different mixing materials. With conventional manufacturing, advanced machining technology is required with multiple setups and custom fixtures.

MIM stainless steel 420 has essential properties for screw extruder elements, such as high hardness and strength after heat treatments. In order to ensure the long lifetime usage and according hardness for materials extruding.

Conclusion

Stainless steel 420 provides an excellent combination of high strength and hardness, as well as corrosion resistance. It is a common material for various stainless steel applications.