Professional MIM Company

Metal Injection Molding Company

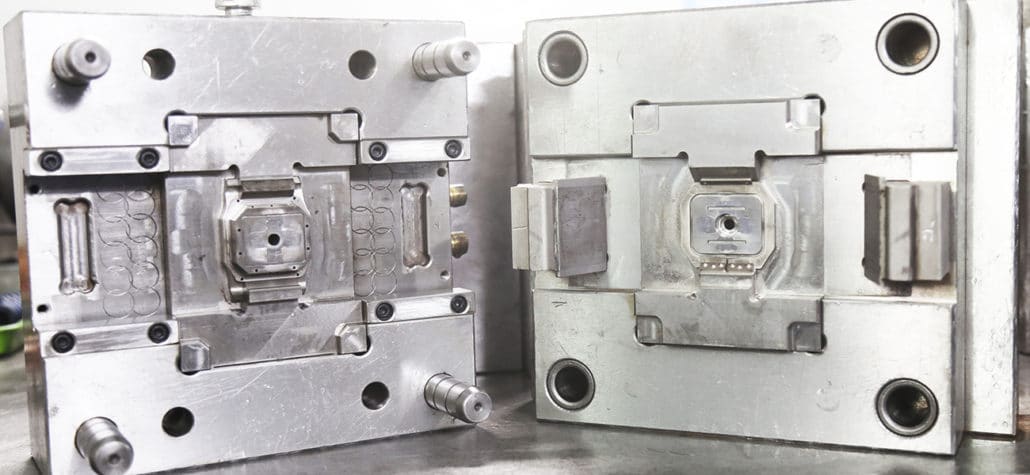

ZCMIM CORPORATION CO.,LIMITED is a professional metal injection molding company in China, specialized in stainless steel injection molding. We have 8,000 square meters of metal injection molding factory, our MIM company can satisfy low, medium and high volume MIM parts operation, it integrates each MIM process like: MIM design, mold design, tool making, debinding, sintering, and surface finishing into final MIM parts inspection and assemble operations.

From 2007, ZCMIM established our high reputation of MIM Manufacturing, our precision MIM parts are most cost-effective with incredible high quality. Our experienced technical team remove any limitation in metal injection molding process, which make us be able to manufacturing any geometries MIM parts with excellent mechanical properties.

Start ZCMIM Virtual Tour from following picture.

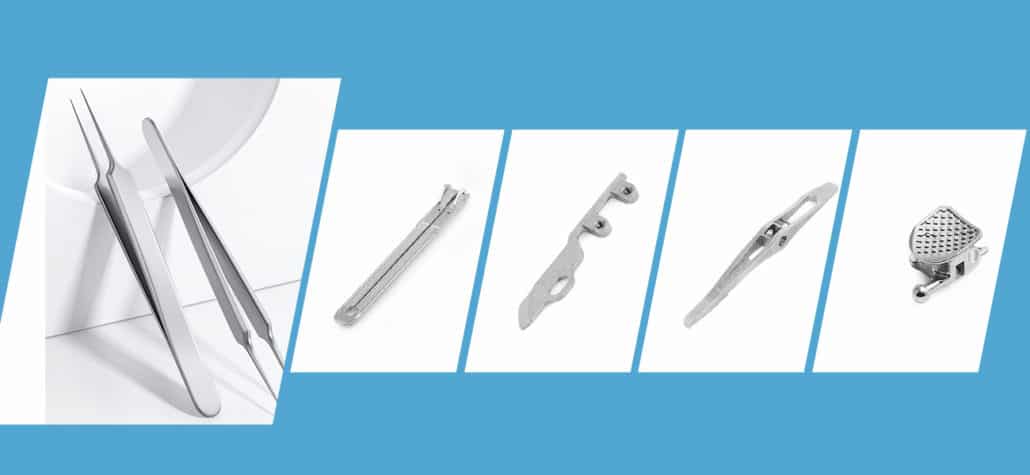

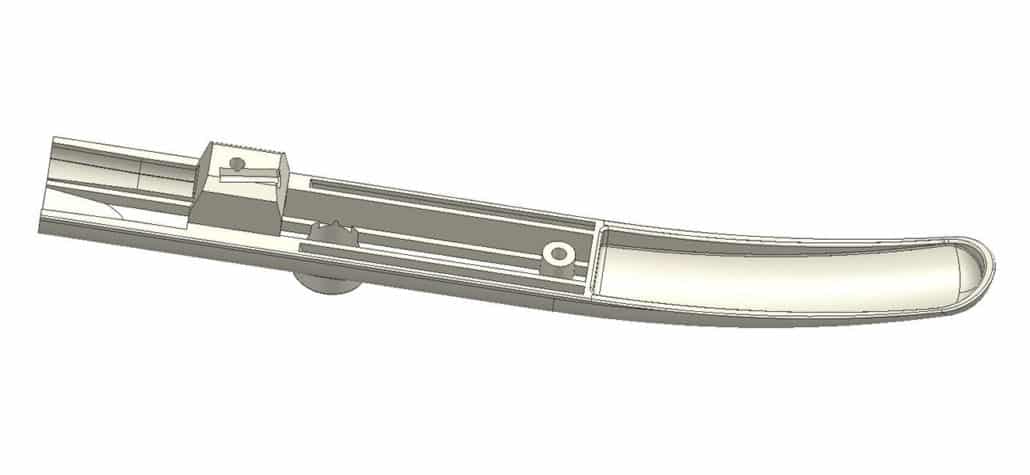

We provide professional metal injection molding service to satisfy your special product development requirement. ZCMIM is your reliable MIM manufacturer, no matter your need simple or complex three dimension structure with high quality and tolerance. Our experienced engineering team combine with advanced MIM technology are able to produce the most wide range of precision MIM parts, including:

1. Electronic, 2. Medical, 3. Industrial, 4. Automotive.

Metal Injection Molding

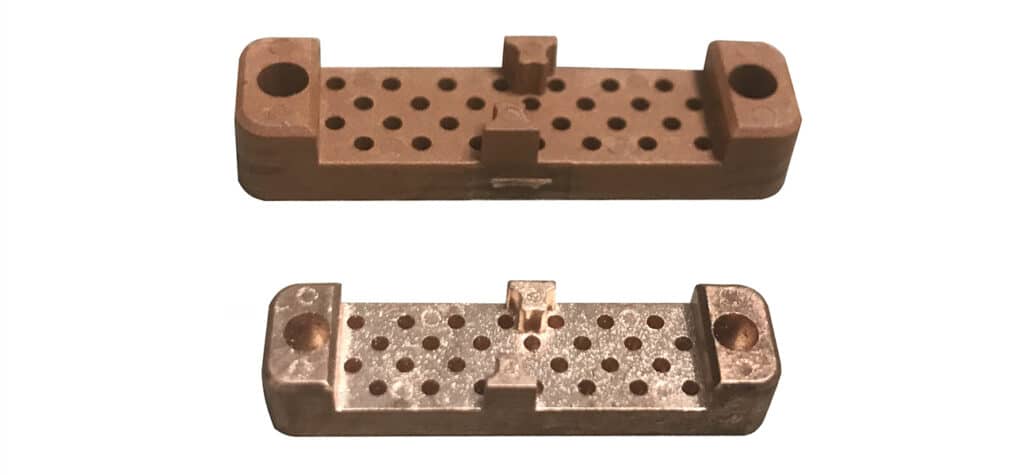

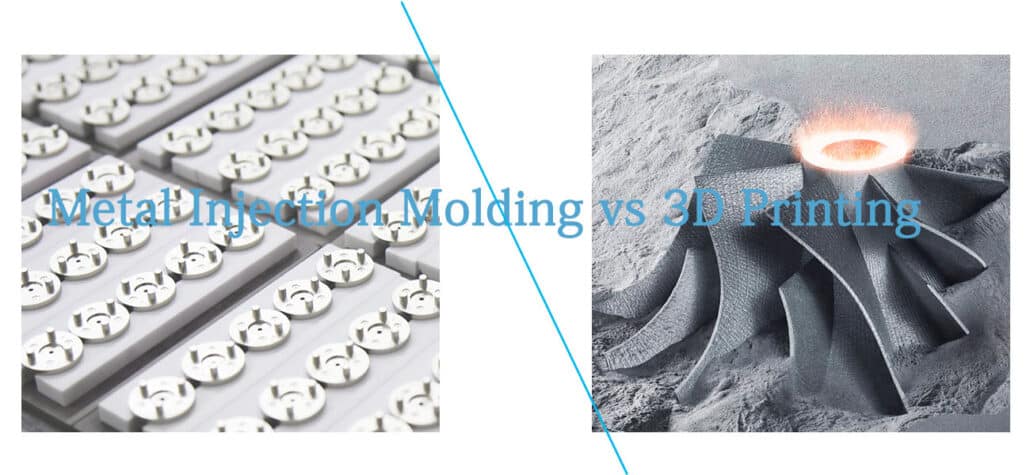

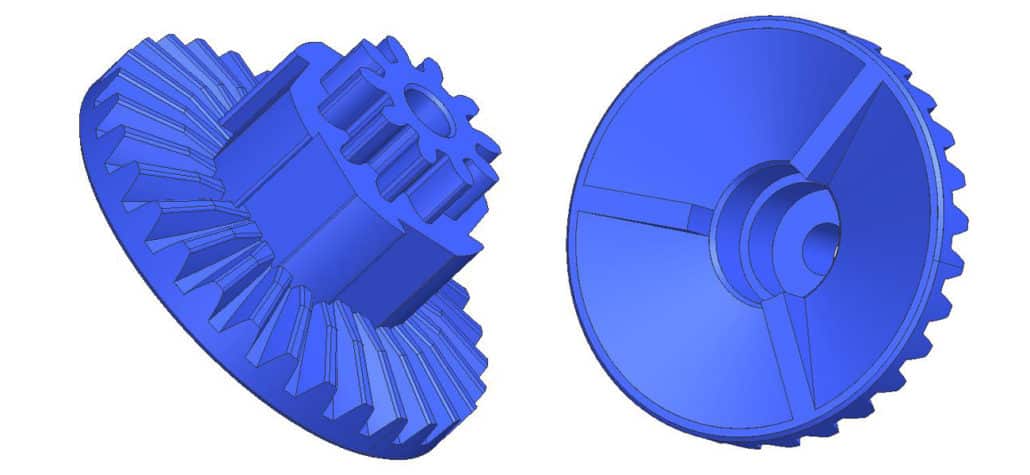

Metal injection molding, also known as MIM, is an advanced metal manufacturing process, which is a cost-effective metal parts production method with high density, complex geometries and excellent properties. This manufacturing process combines metal powder, injection molding and sintering technologies together, in order to guarantee MIM parts can be complex with tight tolerance as well as excellent surfaces.

ZCMIM will cooperate with you to assess the feasibility for MIM production cost, material and manufacturing.

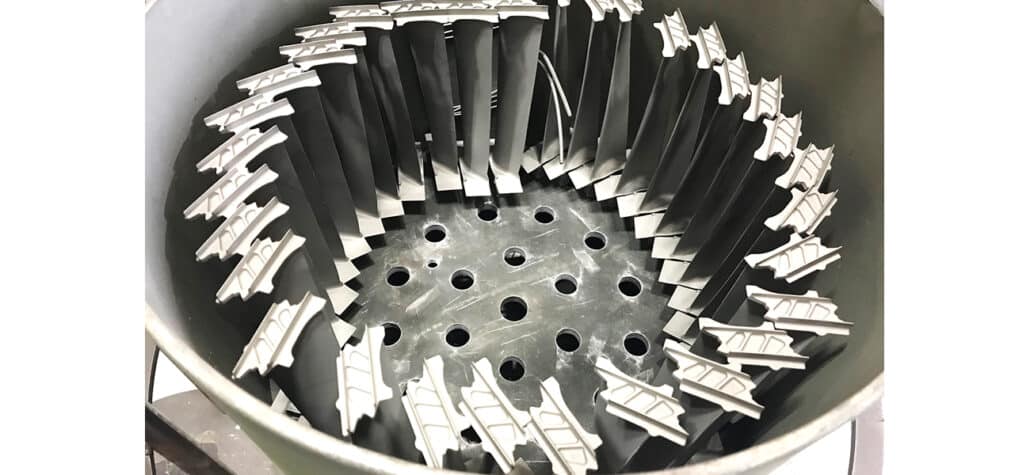

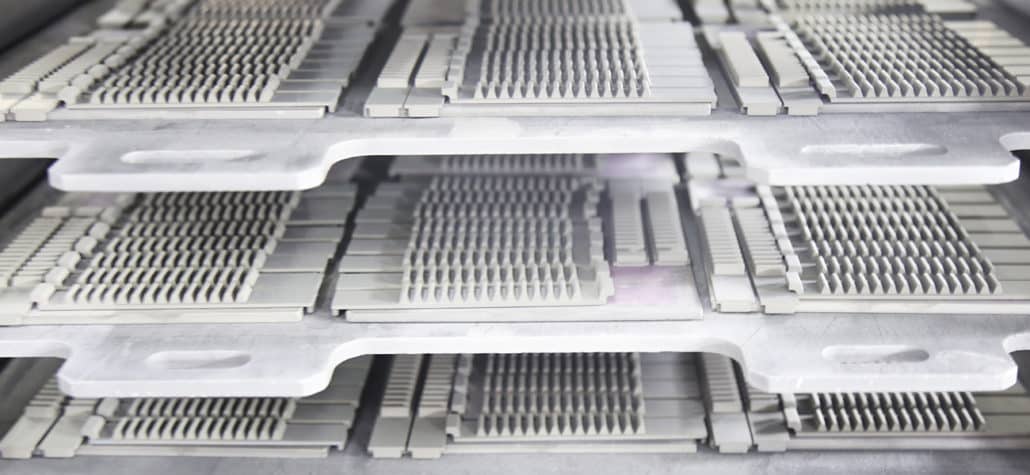

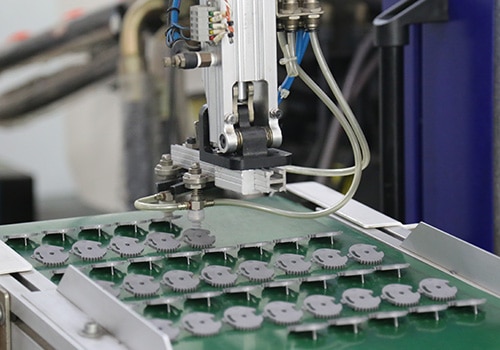

Our main step of MIM including: Compounding, Injection molding, Debinding, Sintering.

Compounding

Injection Molding

Debinding

Sintering

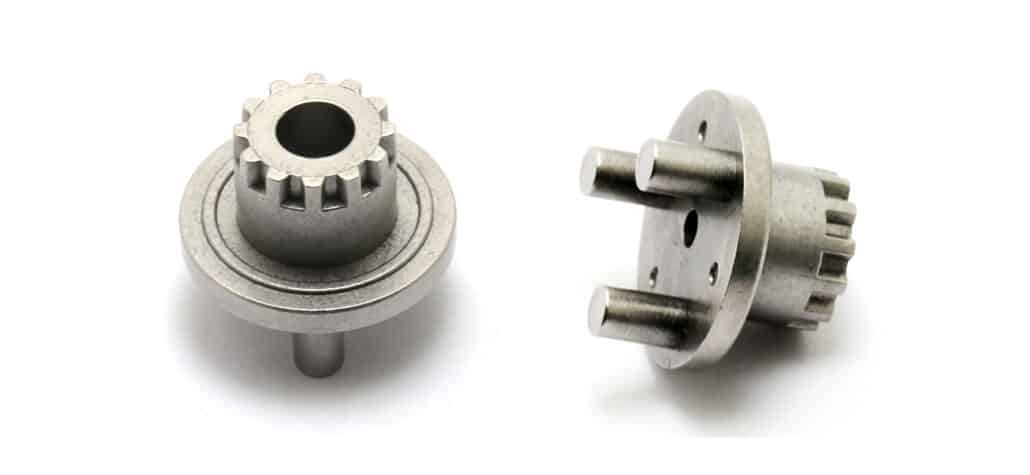

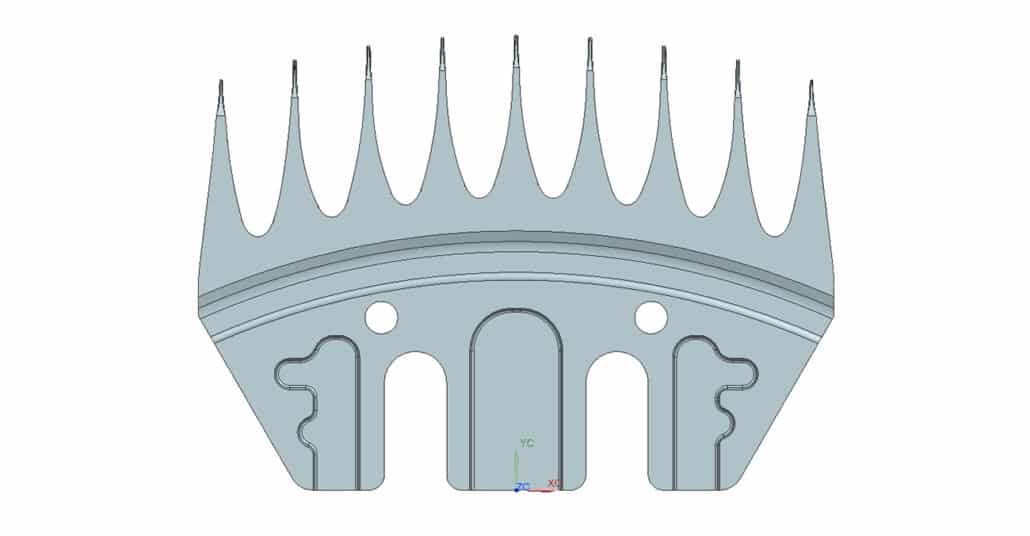

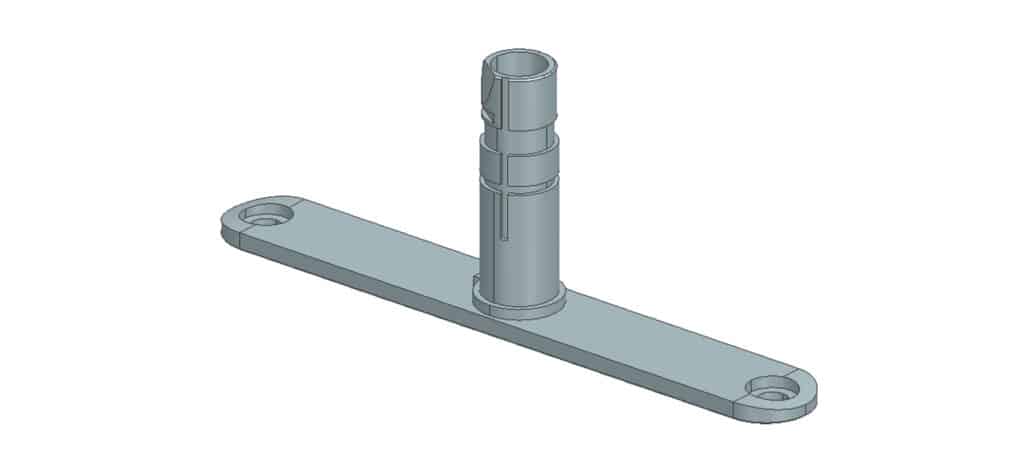

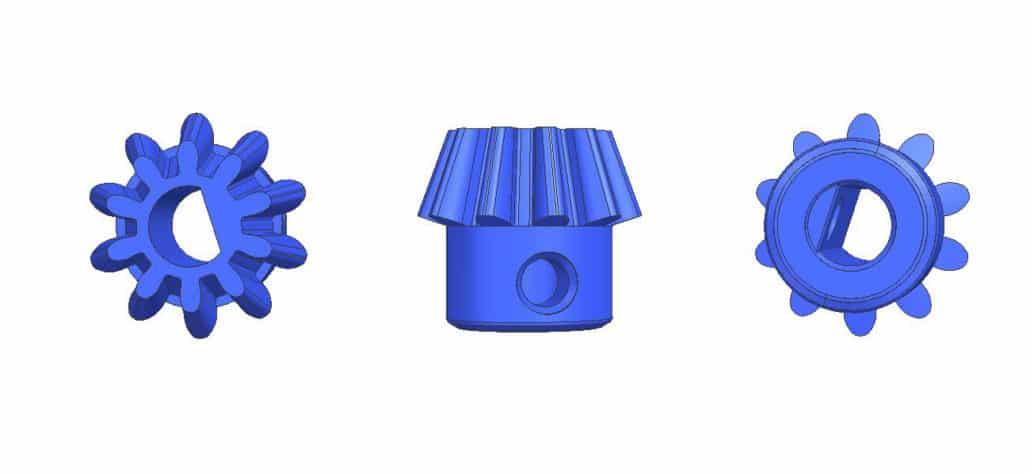

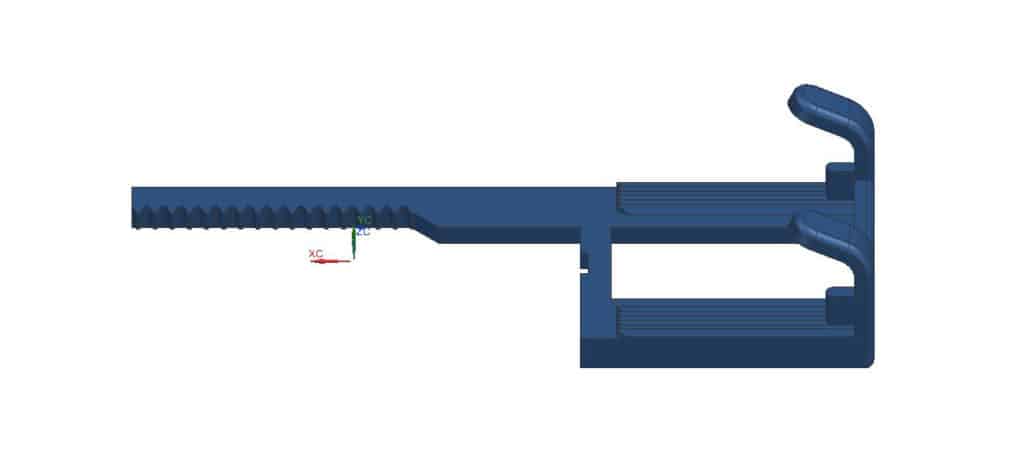

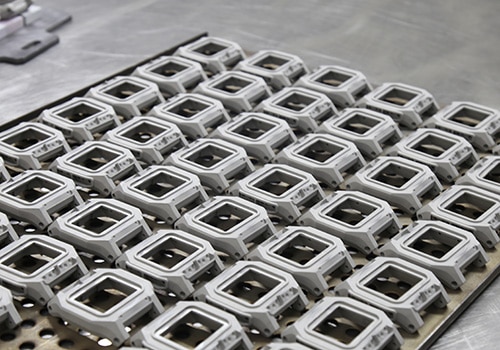

MIM Parts

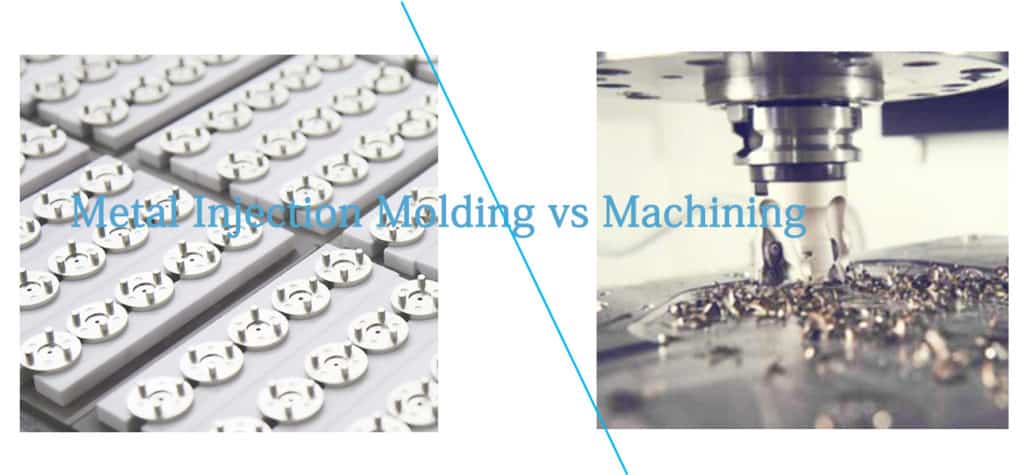

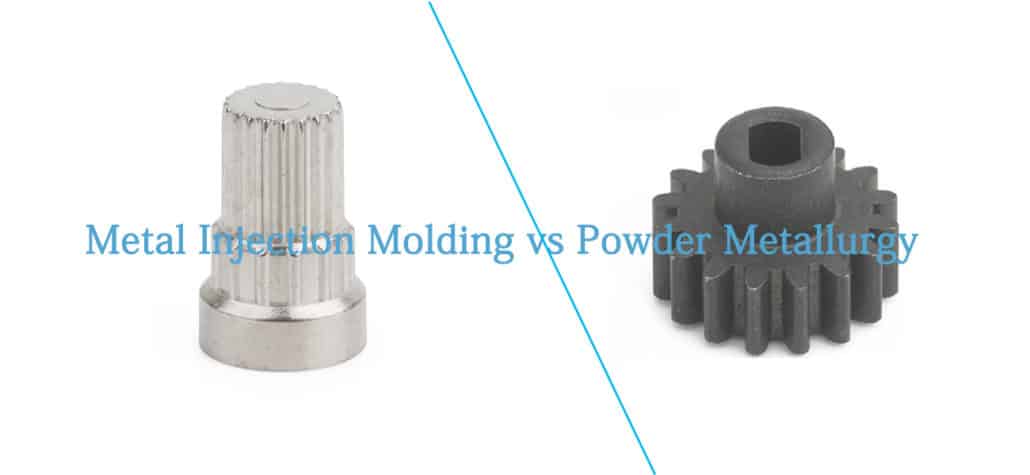

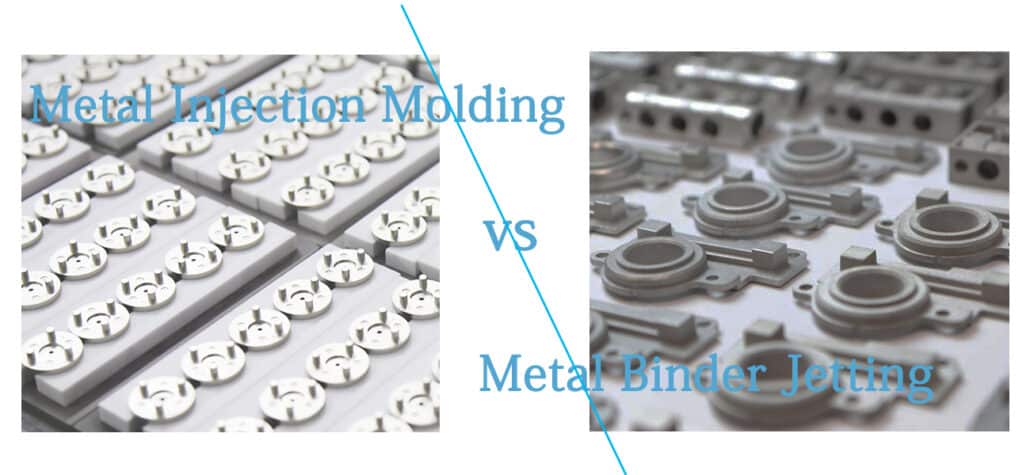

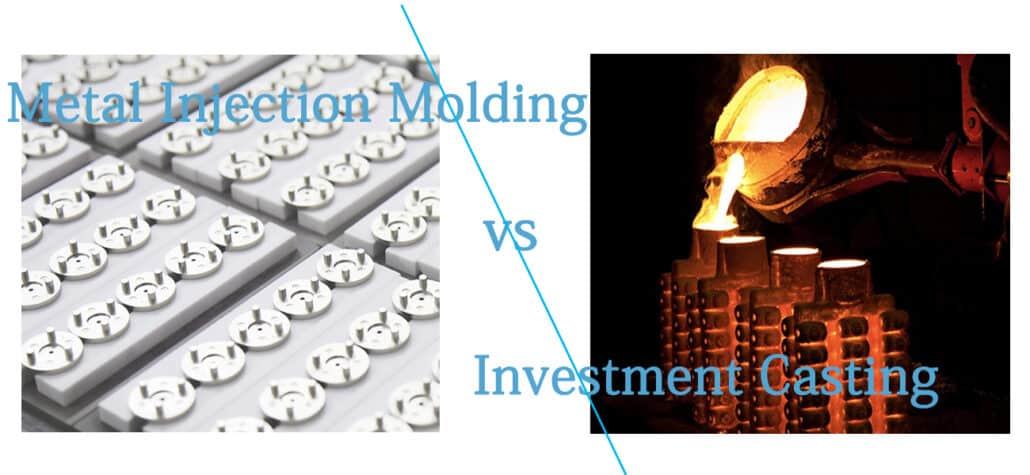

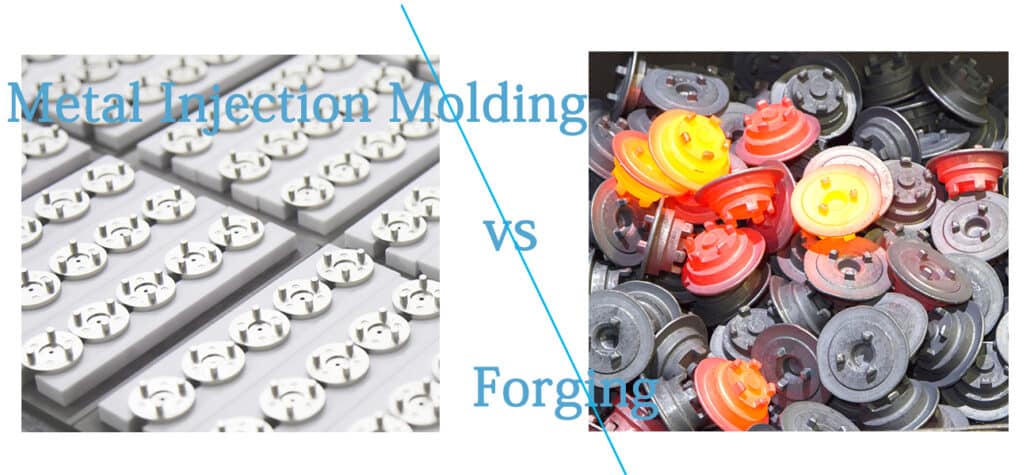

MIM parts are complex metal parts produced by metal injection molding technology, which is a new metal components manufacturing method. Comparing to conventional metalworking method like forging or casting. Metal injection molding has better performance in small size, complex geometries metal parts production with high volume quantities.

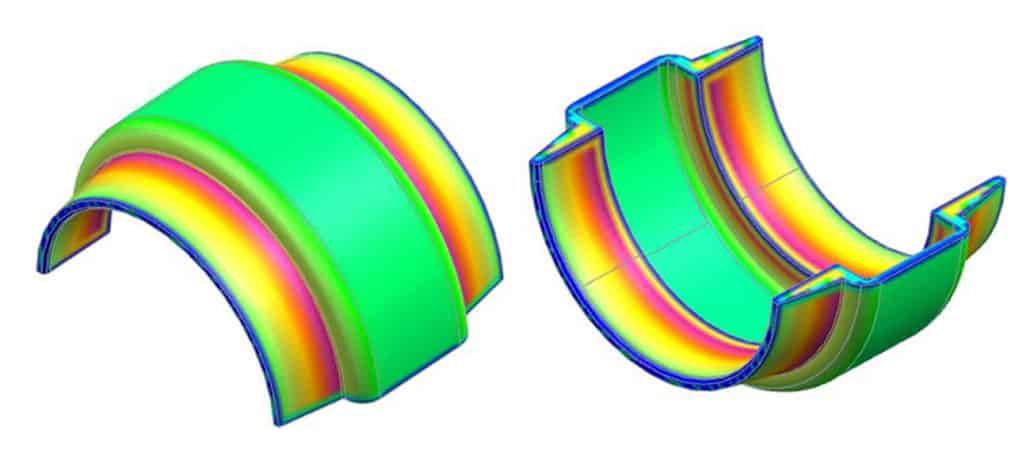

Metal injection molding form metal parts shape with injection molding process, which is similar to plastic injection molding and high-pressure die casting. However, MIM parts are able to perform high mechanical properties equal to wrought materials, and excellent dimensional tolerance control.

MIM parts are normally full density, which has excellent mechanical, corrosion resistance and hermetic sealing properties. In addition, secondary operations, such as plating, heat treating and machining can be easily performed.

ZCMIM Advantages

Metal Injection Molding (MIM) has several advantages over traditional metal production technologies. As 30 years continuous development of MIM technology, ZCMIM can apply this technology producing MIM parts with high volume, various alloys, different size and complex structure. Our summary of MIM advantages as following:

Small Size

Design Complexity

Powerful Capacity

High Tolerance

Delicate Appearance

Flexible Materials

Excellent Properties

Environment Economical

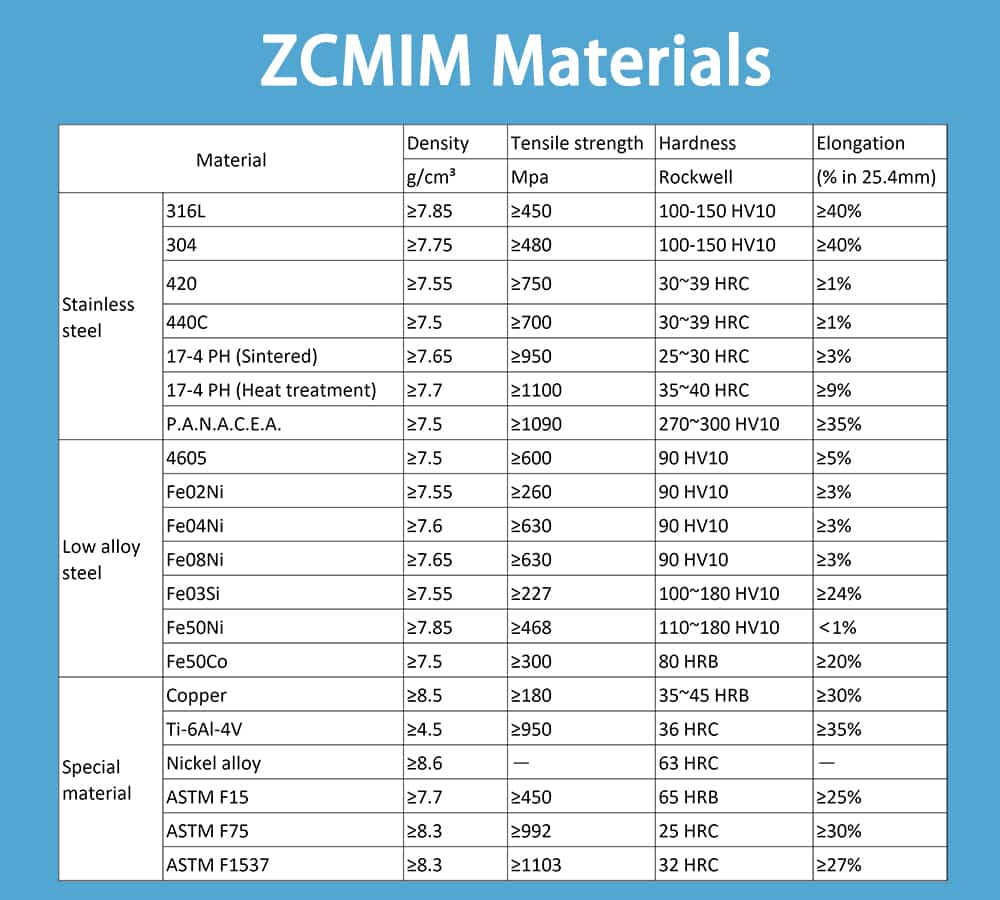

MIM Materials

ZCMIM provide various MIM metal options for specific property requirement, our MIM metal materials usually are divided into following types in functions.

Stainless steel

Low steel alloy

Specific alloy

In addition, ZCMIM also provide custom MIM materials for our customers with high performance in any properties.

Start Your MIM Project Now